IB236

VW DMF to Solid Flywheel

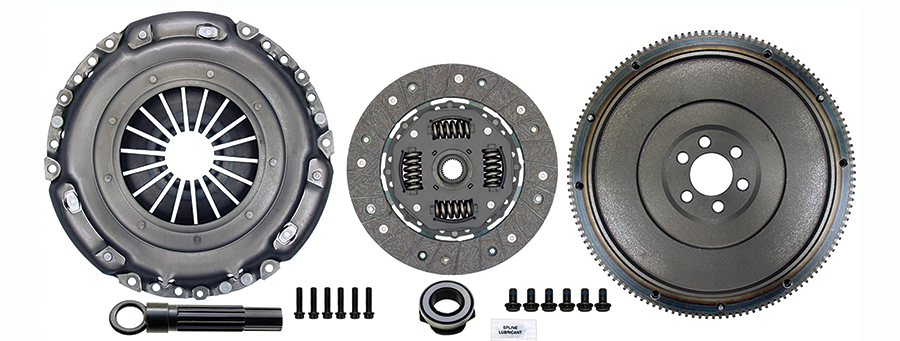

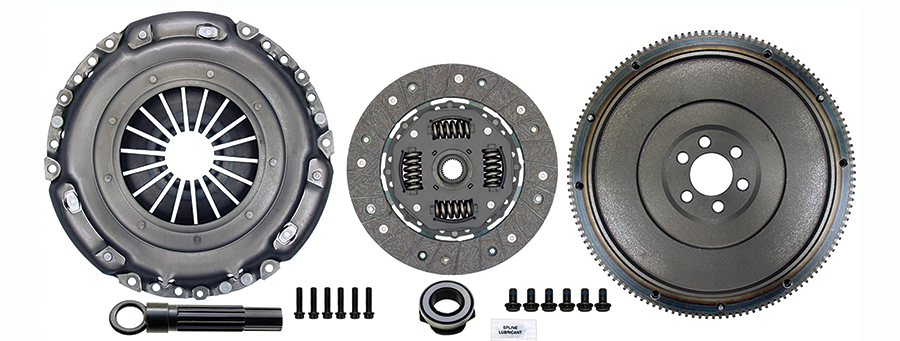

This solid flywheel conversion system is used to replace the original Dual Mass Flywheel (DMF) and clutch system.

Removal of clutch and DMF

After removal of the transaxle:

- Remove the clutch cover. Some systems use a 6mm 12 point serrated wrench while others use a 9mm 12 point socket. Remove all of the clutch cover to DMF attaching bolts.

- Remove the clutch cover and clutch disc.

- Using a 12mm 12 point serrated wrench, remove the 6 DMF to crankshaft bolts. CAUTION: do not drop the DMF.

- Clean the crankshaft to flywheel mounting surace and the 6 flywheel bolt holes.

Conversion System Installation

- Note: the flywheel is indexed to the crankshaft and only installs in one position. Insert and start the 6 ne flywheel bolts furnished with this clutch set. The flywheel bolts are tightened in a three step tightening procedure.

- Using a diagnol tightening pattern, tighten the flywheel bolts to 30 Nm, 22 lb-ft.

- Using a diagnol tightening pattern, tighten the flywheel bolts to 60 Nm, 44 lb-ft.

- Using a diagnol tightening pattern, turn each bolt an additional 1/4 turn, 90 degrees.

Clutch Installation

- Thoroughly clean the transaxle input shaft of all dirt, grease and rust.

- Using the supplied spline lube grease pack, lightly lubricate the input shaft spline. With clean hands ,slide the disc onto the input shaft distributing the grease, wipe up any excess. Do not allow the grease to contaminate the friction surface of the clutch disc.

- Using a brake cleaning product or rubbing alcohol, thoroughly clean the friction surfaces of the flywheel and pressure plate casting surfaces, it is not necessary to clean the friction material of the clutch disc.

- Place the disc into the pressure plate and place the disc and cover on the flywheel. Center the disc using the pilot tool.

- The clutch cover only lines up in one position on the flywheel, rorate to align the clutch cover with the dowl pins. Start the new clutch cover bolts.

- Using a diagnol tightening pattern, tighten the clutch cover bolts 1/2 turn at a time. Continue diagnolly tightening of the clutch cover until it is seated on the flywheel. Finish tightening the bolts by torquing to 20 Nm, 15 lb-ft.

Test Drive

This solid flywheel clutch set replaces a DMF system. Under certain drivetrain loads, gear selection and engine RPM, a slight transmission gear noise may be heard. This is normal for conversion from DMF to solid flywheel clutch systems.

PLEASE REFER TO FACTORY SERVICE MANUALS FOR DETAILED APPLICATION SPECIFIC PROCEDURES.

This bulletin is to assist in the safe and effective servicing of this application. Transmissions, transaxles and transfer cases are heavy and their safe removal and replacement requires the use of proper tools, equipment and procedures to prevent injury and damage. Always read and follow instruction bulletins and factory service manuals for detailed clutch servicing procedures.

Bulletins and any additional information:

IB236 06/23/2015