IB284

IB284 - Flexible Braided Clutch Hose Installation

This flexible braided hose replaces the rigid or molded hose for the cataloged applications.

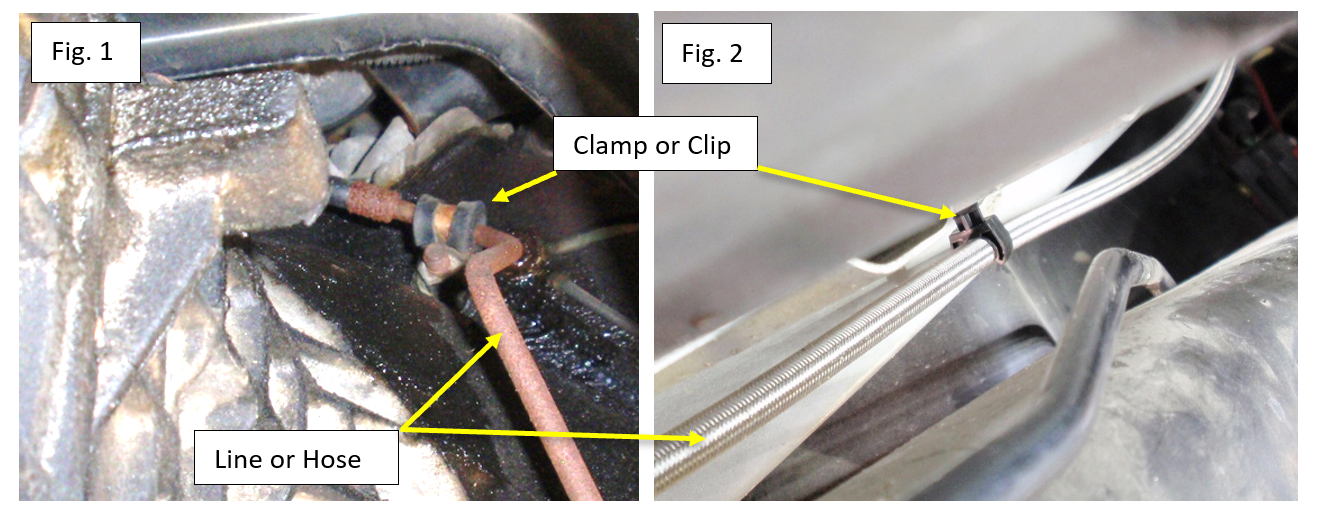

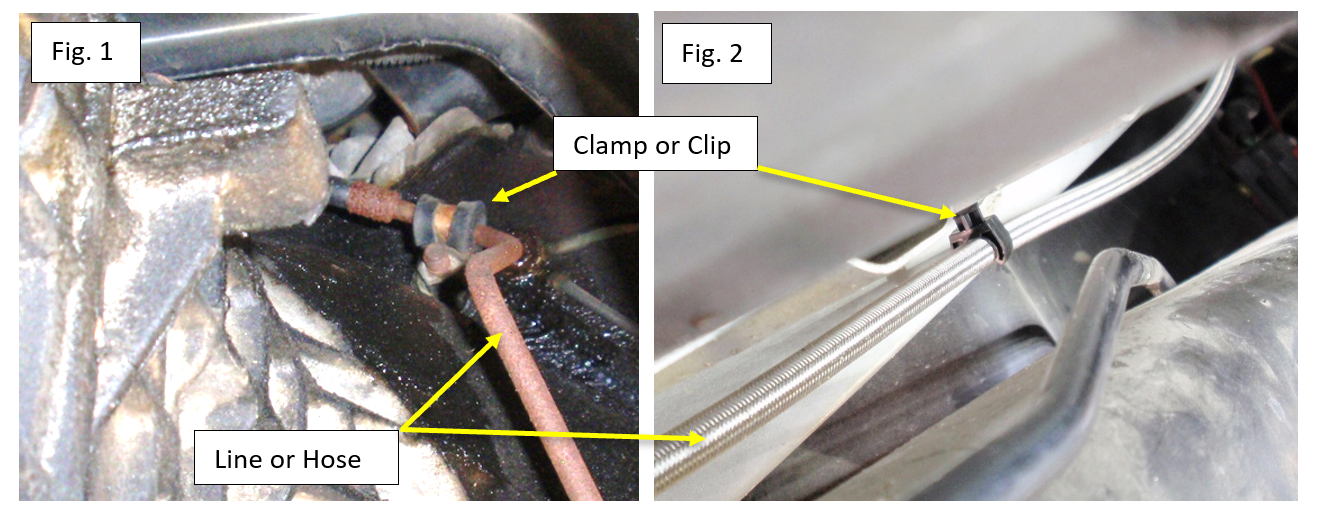

1. Prior to removing the old hose note the routing and position of the old hose and any clamps or clips that position or route the hose.

2. Any hose clamps or clips can be reused using the same locations, see Fig. 1 and 2.

3. This system will require bleeding.

4. Use flare nut wrenches on flare nut connections.

5. To assemble any flare nut connection, carefully thread the nut in by hand several turns prior to using a wrench and check final routing prior to tightening.

6. Roll pin and O-ring type connections can be disassembled with a 1/8” or 3mm straight pin punch and carefully tapping the pin out with a small hammer and suitably supporting the cylinder.

7. To assemble the roll pin and O-ring connection, place the O-ring on the barbed end, lubricate with DOT 3 Brake Fluid in insert into the cylinder fully. Tap the roll pin into the cylinder to retain the fitting.

8. Prior to mounting the master and slave cylinder go to www.clutchtechsupport.com enter the part number of the master or slave cylinder for appropriate bleeding techniques.

9. Carefully route the flexible braided clutch hose away from any sharp edges and from any exhaust pipes or exhaust manifolds. Tie straps are included, please use to safely attach as required.

PLEASE REFER TO FACTORY SERVICE MANUALS FOR DETAILED APPLICATION SPECIFIC PROCEDURES.

This bulletin is to assist in the safe and effective servicing of this application. Transmissions, transaxles and transfer cases are heavy and their safe removal and replacement requires the use of proper tools, equipment and procedures to prevent injury and damage. Always read and follow instruction bulletins and factory service manuals for detailed clutch servicing procedures.

Bulletins and any additional information:

IB284 05/17/2017