IB272

External Slave Cylinder Pushback Bleeding

Clutch Hydraulic Release Systems

Requirements:

- External slave cylinder.

- Works best with a slave cylinder mounted on the same side of the vehicle as the master cylinder.

- A master cylinder that in some installations can be tipped to allow the trapped bubble to burp out thru the reservoir.

Air bubbles in a clutch hydraulic release system can often be pushed up and out the system using the slave cylinder to push the fluid up into the reservoir, carrying the bubbles out.

Remove the slave cylinder from the transmission. If it has straps retaining the pushrod, compress the slave cylinder and temporarily disconnect the straps. The straps can be connected after bleeding the system. If the entire system can be removed completely removed from the vehicle that can allow bubbles to burp out quickly and easier.

Position the slave cylinder, line as required, and or master cylinder so a trapped air bubble has a continuous upward path to the fluid reservoir. Carefully compress the slave cylinder completely by hand. Carefully allow the slave cylinder to extend to its full length. Repeat the compression and extension cycles. If an observer is available and can watch the reservoir for bubbles appearing in the fluid during slave cylinder compressions this will confirm the process.

Repeat the compressions until no more bubbles appear after several cycles. Left picture shows compression technique, picture on the right shows bubbles bursting in the reservoir.

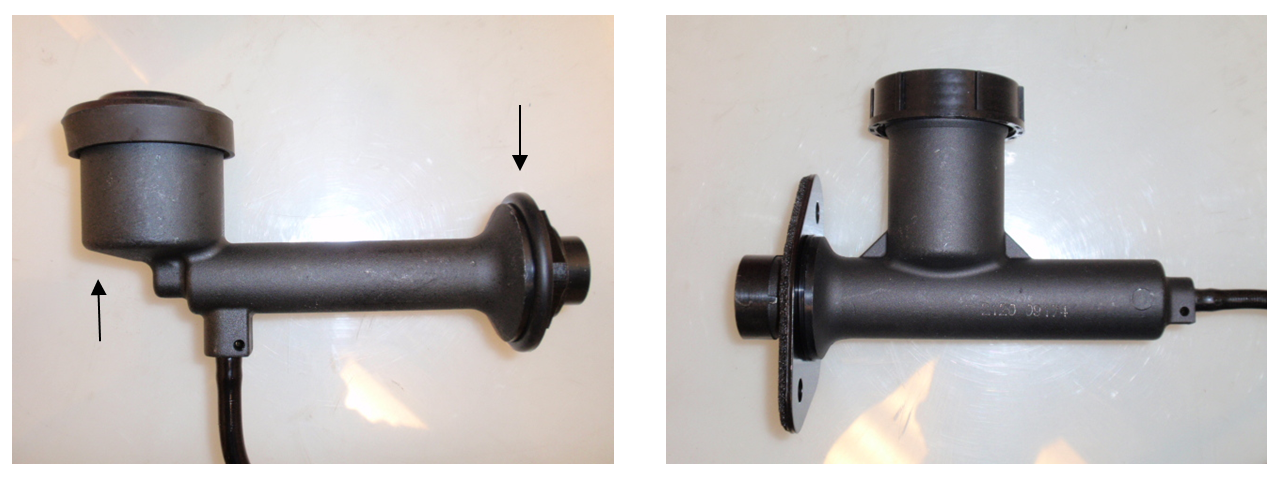

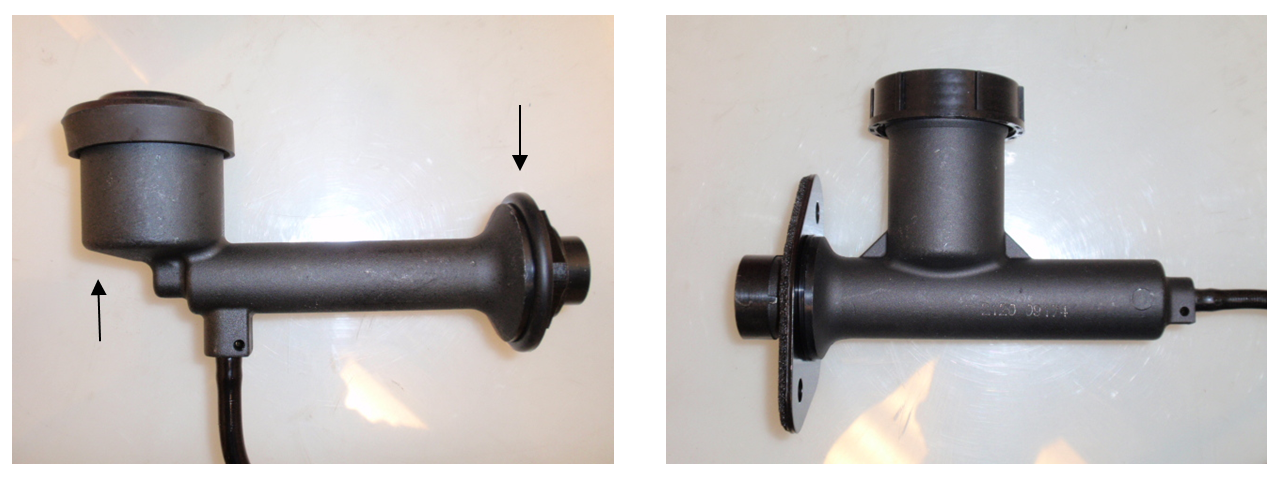

The master cylinder design on the left requires that the pushrod end is tipped down 30-45 degrees from horizontal for the air bubbles to burp out through the reservoir. The design on the right must be horizontal or pushrod end slightly elevated for the bubbles to burp out.

PLEASE REFER TO FACTORY SERVICE MANUALS FOR DETAILED APPLICATION SPECIFIC PROCEDURES.

This bulletin is to assist in the safe and effective servicing of this application. Transmissions, transaxles and transfer cases are heavy and their safe removal and replacement requires the use of proper tools, equipment and procedures to prevent injury and damage. Always read and follow instruction bulletins and factory service manuals for detailed clutch servicing procedures.

Bulletins and any additional information:

IB272 06/25/2015